The HVAC system in a car—short for Heating, Ventilation, and Air Conditioning—controls the temperature and airflow inside the cabin. Its job is to keep things comfortable by cooling, heating, and managing humidity. To cool the air, it uses a refrigeration cycle. For heat, it relies on the engine’s warmth. The system includes several main parts: the compressor, condenser, evaporator, and expansion valve—all working together to keep you comfortable in any weather.

Automotive HVAC systems are found in almost every car today, from small sedans to heavy-duty trucks. These systems control the air inside your vehicle, making sure you stay comfortable no matter the weather outside. But there’s more to it than just making your car cool in summer or warm in winter.

HVAC systems in vehicles are specially designed to work with a car’s engine, refrigerant, and blowers to regulate temperature and air quality. Over time, the automotive industry has put a lot of focus on making these systems more efficient due to changing climate needs and new car technology, like electric vehicles.

In this guide, we’ll break down how automotive HVAC works, why it matters, and the role each part plays in keeping your car cozy and fresh. We’ll also discuss different types of blower motors and why some are better for electric vehicles than others.

Whether you’re a car enthusiast, a beginner, or just want to know how your car’s air system works, this guide is here to help. Let’s dive into the details!

What Is Automotive HVAC Systems?

Automotive HVAC, short for Heating, Ventilation, and Air Conditioning, refers to the system that regulates air quality and temperature inside vehicles. This includes cooling in summer, heating in winter, and ventilation to maintain air purity. Originally a luxury, HVAC systems are now standard in nearly all vehicles due to the significant comfort and health benefits they bring. Let’s explore what this system is, its components, and why it’s so essential.

Key Functions of Automotive HVAC Systems

The main goal of the HVAC system is to keep the car cabin comfortable and the air quality safe to breathe. It achieves this by managing:

- Temperature – Keeps the interior cool or warm, based on the climate outside.

- Humidity – Controls moisture levels, so the air isn’t too dry or too humid.

- Air Purity – Filters out dust, allergens, and other pollutants.

- Airflow – Moves fresh, clean air throughout the cabin.

Without these functions, driving would be uncomfortable, especially during extreme weather conditions. But automotive HVAC is more than just convenience; it’s about safety too. Clear air and stable cabin temperatures help drivers stay focused on the road, reducing risks related to discomfort or distraction.

Core Components of Automotive HVAC Systems

The HVAC system is made up of several components, each with a specific role:

- Compressor

- The “heart” of the cooling process. It pumps refrigerant through the system and starts the process of transforming hot air into cold.

- Condenser

- Located near the front of the vehicle, it cools the refrigerant as it moves through, turning it from a hot gas to a liquid.

- Receiver Dryer

- Filters out moisture and impurities from the refrigerant to prevent corrosion and freezing issues.

- Expansion Valve

- Releases refrigerant into the evaporator, cooling it down significantly before it enters the cabin.

- Evaporator

- Absorbs heat from inside the car, making the air cool. It’s typically located behind the dashboard.

- Blower

- Blows cooled or heated air through the vents into the car interior, circulating it throughout the cabin.

- Thermostat and Actuator

- The thermostat regulates temperature, while the actuator directs airflow to the right places, like the windshield or feet.

Each component works together in a seamless loop. When you set the desired temperature, these parts interact to either heat or cool the air and distribute it evenly throughout the vehicle.

Why Automotive HVAC Systems Are Essential

Automotive HVAC systems have become increasingly important due to rising global temperatures and consumer demand for better air quality. Many newer vehicles even include air purification features, which help filter out not only dust but also allergens, pollutants, and bacteria. These features improve safety and comfort, especially for people with respiratory issues, such as asthma.

Beyond comfort, HVAC systems support the growing trend toward electric vehicles (EVs), which require efficient systems that don’t drain battery life. Electric vehicles often have high-efficiency HVAC systems to keep energy use low, a priority for any battery-powered system.

Example:

Modern EVs, like the Toyota Prius Prime, are engineered with advanced HVAC systems that keep the interior comfortable while using minimal power. This approach allows drivers to maximize their EV’s range even when the weather is extreme.

How Automotive HVAC Differs from Other Systems

While HVAC systems are also found in homes and offices, automotive HVAC systems must be more compact and robust to handle constant vibration, temperature extremes, and compact installation spaces. Here are a few ways automotive HVAC differs:

- Smaller Size – Fits within the vehicle dashboard, unlike larger systems in buildings.

- Efficiency Needs – Must perform well without draining the vehicle’s fuel or battery.

- Durability – Designed to withstand road bumps and vibrations over years of use.

These factors mean that automotive HVAC systems are carefully engineered to last longer and run efficiently, even under challenging conditions.

Automotive HVAC Systems and Climate Control

Some cars, especially luxury models, come with automatic climate control. This feature maintains a set cabin temperature without needing manual adjustments. Sensors monitor the cabin’s climate, and the system makes adjustments to fan speed, temperature, and airflow.

In summary, automotive HVAC systems offer drivers and passengers a controlled, comfortable environment. With rising temperatures and increasing concerns about air quality, these systems are evolving to meet consumer needs, ensuring that every drive is both comfortable and safe.

How Automotive HVAC Systems Work

The HVAC system in a car is crucial for keeping the cabin comfortable. Let’s break down each part of the system to understand how cooling and heating work.

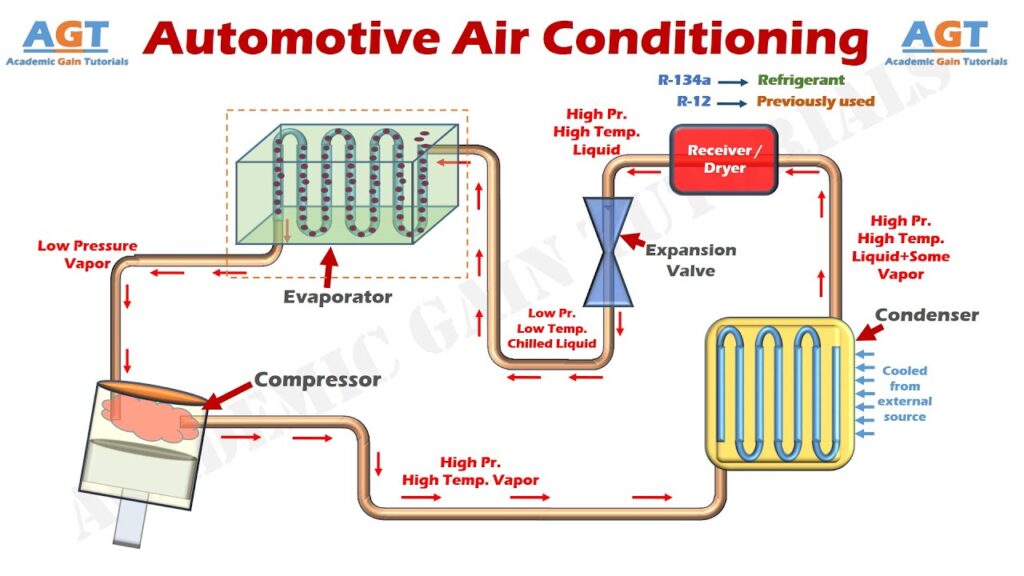

How Automotive Cooling Works

Automotive cooling is the process that makes hot air cool inside a car. It all starts with a refrigerant, a special substance that can change between gas and liquid forms. The refrigerant goes through a cycle involving several components:

- Compressor:

The compressor is like the heart of the HVAC system. It takes the refrigerant gas, squeezing it tight to make it hot and pressurized. This step is essential to turn the gas into a high-temperature, high-pressure state. - Condenser:

Once compressed, the refrigerant moves to the condenser. Here, outside air cools down the hot refrigerant, changing it from gas to liquid. This part of the process lowers the temperature of the refrigerant. - Receiver Dryer:

The next stop is the receiver dryer, which removes moisture and dirt from the liquid refrigerant. Moisture can damage the system, so this step is critical for long-term function. - Expansion Valve:

Now that the refrigerant is clean and cooled, it heads to the expansion valve. This valve sprays the liquid into a low-pressure mist, cooling it even more before sending it to the evaporator. - Evaporator:

The evaporator is where the magic happens. As the refrigerant evaporates back into gas, it absorbs heat from the cabin air, making the air inside the car cooler. - Blower:

Finally, the blower sends this cold air into the cabin, where it circulates to keep everyone comfortable.

How Automotive Heating Works

Heating is simpler than cooling. Instead of using refrigerant, the HVAC system uses the heat generated by the engine. Here’s how it works:

- Engine Coolant Heats Up:

As the engine runs, it generates a lot of heat. Engine coolant absorbs some of this heat to prevent the engine from overheating. - Heater Core:

The warm coolant flows to a device called the heater core, which acts like a mini radiator inside the HVAC system. The heater core warms the air that passes over it. - Blower Fan:

The blower fan pushes this warm air from the heater core into the cabin. This process provides warmth on cold days, ensuring a cozy ride.

The Role of the Blower Fan

The blower fan is essential to both heating and cooling. It controls the speed and direction of the airflow, distributing warm or cool air as needed. Automotive blower fans come in a few types, such as axial, diagonal, and cross-flow fans. However, most cars use centrifugal fans, especially the multi-blade (sirocco) type. Here’s why:

- Centrifugal Force:

These fans use centrifugal force, where the spinning motion creates air pressure, moving air efficiently through ducts. - Multi-Blade Design:

The multi-blade (sirocco) design includes forward-angled blades. This structure allows for a balanced air output, keeping airflow steady.

Types of Blower Motors: Brushed vs. Brushless DC

The blower fan’s motor type affects its efficiency and durability. Two types are commonly used:

- Brushed DC Motors:

Older cars often use brushed DC motors. They are simple and reliable but may wear down due to friction over time. - Brushless DC Motors:

Many modern cars now use brushless DC (BLDC) motors. These motors don’t have brushes, meaning there’s less wear and tear. BLDC motors are also quieter and more energy-efficient, ideal for electric vehicles or vehicles with advanced HVAC systems.

Visualizing the HVAC System Workflow

For a visual summary, here’s a simple diagram to show how air moves through an automotive HVAC system. This helps you see how each part works in harmony to keep the cabin comfortable in all seasons.

Image: How air flows through an HVAC system from compressor to blower.

Each part of the HVAC system has a role, from cooling to heating. A working HVAC system depends on all of these parts. Understanding how it all works helps in maintaining and diagnosing problems in your car’s HVAC system, ensuring comfort all year round.

Types of Blower Motors in Automotive HVAC

Automotive HVAC systems need powerful blower motors to circulate air effectively. These motors push air through the system, allowing warm or cool air to reach the car cabin. Let’s take a closer look at the two main types of blower motors used in these systems and how they affect performance, durability, and even fuel efficiency.

1. Brushed DC Motors

Brushed DC motors have been used for decades in various automotive applications, including HVAC systems. Here’s how they work and what makes them unique:

- How They Work: Brushed DC motors use brushes and commutators to create rotation. The brushes, typically made of carbon, make contact with the commutator, which helps power flow to the motor’s rotating part (the armature). This contact powers the motor, creating the force to turn the fan.

- Advantages: These motors are simple and cost-effective. Because they’ve been around for a long time, they are widely understood and easy to repair.

- Drawbacks: Brushes wear out over time due to friction, which can reduce performance and eventually lead to motor failure. They can also be noisier and less efficient than newer types of motors, which can affect the overall comfort and longevity of the HVAC system.

Use Cases

Brushed motors work well in standard vehicles where cost is a concern and minimal noise isn’t an issue. They are also found in vehicles that do not require high-efficiency HVAC systems, such as some compact cars and older models.

2. Brushless DC Motors (BLDC)

Brushless DC motors are a newer option in the automotive HVAC world. Instead of using brushes, these motors rely on electronic circuits, which control the current flow to achieve the same rotational motion without physical contact.

- How They Work: BLDC motors use an electronic controller that delivers current to the motor’s coils in a precise sequence. This allows for smoother operation and removes the need for brushes and commutators.

- Advantages:

- Longer Life: Without brushes, BLDC motors don’t suffer from the same wear and tear. This means they can last significantly longer than brushed motors.

- Quiet Operation: Because there’s less friction and mechanical noise, BLDC motors are quieter—a key factor in a vehicle’s cabin comfort.

- Higher Efficiency: BLDC motors are more efficient, helping reduce power consumption, which is especially important in electric vehicles (EVs). This efficiency can lead to a slight improvement in battery life and fuel economy.

- Drawbacks: The main downside of BLDC motors is their higher cost. They require more complex electronics, which can make them a pricier option for manufacturers.

Use Cases

Due to their high efficiency and low noise, BLDC motors are popular in premium vehicles and electric cars, where quiet cabin space and sustainability are critical. Many manufacturers are also adopting them to align with stricter environmental regulations and consumer demand for sustainable automotive technology.

Comparison of Brushed vs. Brushless Motors

Here’s a quick comparison of both types of blower motors to make their differences clearer:

| Feature | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

| Durability | Moderate, requires regular maintenance | High, low maintenance |

| Noise | Louder, due to friction | Quiet operation |

| Efficiency | Less efficient | High efficiency, great for EVs |

| Cost | Lower | Higher, more complex electronics |

| Preferred Use | Standard vehicles, cost-conscious models | Premium, electric, and eco-friendly cars |

Expert Insight: Why Brushless Motors Are Gaining Popularity

As electric and hybrid vehicles gain popularity, manufacturers are looking for components that are not only reliable but also energy-efficient and quiet. Brushless motors fit this need perfectly. Their low noise and high efficiency align well with the quiet operation of EVs, which is why more brands are shifting to BLDC for HVAC applications.

Did You Know?

Many electric vehicle manufacturers are moving toward fully electric HVAC systems using brushless motors. This trend helps reduce the drain on EV batteries, contributing to longer driving ranges and less frequent recharging.

When choosing the right automotive HVAC blower motor, it’s essential to weigh the benefits of both types. Brushed motors may be cheaper, but they require more maintenance. Brushless motors, on the other hand, offer longer life and efficiency.

Engineering Role in Automotive HVAC Technology

Automotive HVAC technology has a critical engineering backbone. Every component, from compressors to blowers, is meticulously designed to handle the demands of heating, ventilation, and air conditioning within a moving vehicle. Engineers play a pivotal role in creating efficient systems that enhance comfort and ensure safe operation under a variety of environmental conditions. Here, we explore key engineering efforts that support HVAC efficiency, sustainability, and integration, focusing on the vital technologies, materials, and testing processes required to meet these goals.

1. Advancements in Core HVAC Components

Engineers continually innovate to make HVAC components smaller, lighter, and more efficient. This is especially critical as vehicles move toward electric power, where battery power must be conserved.

- Compressor

The compressor is the heart of the HVAC system. Engineers have developed new compressor designs that use less power without sacrificing cooling capacity, which is essential for extending EV range. - Condenser and Evaporator

By refining the materials and design of the condenser and evaporator, engineers maximize heat exchange, reducing the load on the compressor.

2. Role of Brushless DC Motors in HVAC Systems

Many modern automotive HVAC systems now use brushless DC motors (BLDC), which are more reliable and durable than brushed motors. Engineers often choose BLDC motors for their advantages:

- Quiet Operation – BLDC motors minimize noise, an important factor in EVs where traditional engine noise is absent.

- Energy Efficiency – Brushless motors are highly efficient, using less power while providing the same airflow.

- Reduced Maintenance – Without brushes, these motors wear less, extending their lifespan.

Expert Insight: When I first started working with BLDC motors in automotive applications, we had to balance efficiency with cost carefully. Now, brushless motors are becoming the industry standard, and we’ve optimized designs to improve both cost and performance.

3. Testing for Reliability in Extreme Conditions

Automotive HVAC systems must endure various conditions, from freezing cold to intense heat. Engineers conduct rigorous tests to ensure HVAC systems perform well under all weather conditions:

- Thermal Cycling: Systems are cycled between extreme hot and cold temperatures to simulate different climates.

- Vibration Testing: Components are subjected to vibration tests to guarantee they withstand the stresses of a moving vehicle.

- Salt Spray Testing: Since vehicles are exposed to salt, especially in colder climates, corrosion tests protect the HVAC system from damage.

HTML Visualization of Environmental Testing Process

Automotive HVAC Environmental Testing

- Thermal Cycling: Up to -40°C to +85°C

- Vibration: Simulates road and engine vibrations

- Salt Spray: Ensures corrosion resistance

4. Sustainability and Environmental Responsibility

As the world focuses on sustainability, engineering practices in automotive HVAC design have evolved to reduce environmental impact. Eco-friendly refrigerants and energy-efficient components are now a standard in newer models.

- Refrigerant Choices: Engineers choose refrigerants with lower global warming potential (GWP) to reduce emissions.

- Lightweight Materials: Lighter HVAC components reduce overall vehicle weight, improving fuel economy and extending battery life in EVs.

5. Engineering Approach to HVAC Blowers

Engineering has been a key player in integrating BLDC motors into automotive HVAC blowers. The engineering team’s expertise has led to blowers that are quieter, more efficient, and longer-lasting, achieving exceptional performance even in high-stress environments.

Anecdote from Engineering: Early in my career, we faced challenges with blower noise in EVs. Adjusting fan blade geometry and fine-tuning motor speed helped us develop quieter solutions that meet the high expectations of today’s EV drivers.

Why Engineering Matters in Automotive HVAC

Engineering is at the heart of automotive HVAC, from designing components that withstand extreme conditions to choosing materials that minimize environmental impact. Thanks to continuous innovation, HVAC systems are evolving to meet the demands of electric vehicles, sustainable practices, and driver comfort, ultimately shaping the future of automotive climate control.

Choosing the Right Automotive HVAC System

Selecting an HVAC system for a vehicle is more than just picking a cooling and heating unit. It involves understanding the parts, efficiency, and suitability of the system for the type of car you drive. When done right, a good HVAC system will keep the air comfortable, energy use efficient, and improve overall driving comfort.

1. Consider the System’s Durability

Automotive HVAC systems handle extreme conditions and cycles of heating and cooling regularly. A good system must withstand these changes. Look for:

- Sturdy Construction: Durable components, like high-quality compressors and blowers, will help the HVAC unit last longer.

- Reliable Motors: Brushless motors are particularly durable, lasting longer and creating less noise than brushed motors.

- Resilient Materials: Components like the receiver dryer should resist moisture well to prevent corrosion.

2. Noise Level Matters

The sound an HVAC system makes might seem minor, but it can affect the overall driving experience. Some systems are quiet, while others produce noticeable noise.

- Quiet Motors: Brushless motors are quieter than brushed types, making them preferable for passenger cars.

- Fan Noise: Consider systems with high-quality fan blades designed to reduce noise without compromising airflow.

Expert Insight: “I’ve seen systems where a poor-quality fan makes so much noise that customers thought there was something wrong with the engine. Always check for noise ratings if you’re sensitive to sound.”

3. Energy Efficiency is Key

An efficient HVAC system saves fuel and can contribute to lower emissions, which is especially crucial for electric vehicles (EVs) that rely on battery power.

- Low Power Consumption: Choose systems with features like variable-speed blowers, which use energy only when needed.

- Advanced Motors: Brushless DC (BLDC) motors are more efficient and generate less heat than brushed motors, which makes them ideal for reducing energy use.

4. Compatibility with Electric Vehicles (EVs)

If you’re choosing an HVAC system for an EV, compatibility is essential. Electric vehicles often rely on highly efficient, lightweight systems due to limited battery capacity.

- Lightweight Design: An ideal HVAC for EVs will be compact and lightweight, preserving battery life.

- Battery-Saving Technology: Some systems are designed specifically for EVs and consume minimal energy, such as those with efficient BLDC motors.

5. Think About Long-Term Costs

While price is an immediate concern, don’t forget to look at long-term costs like maintenance and potential repairs. High-quality systems may cost more upfront but save money over time.

- Fewer Repairs: Well-built HVAC systems with brushless motors require less frequent maintenance.

- Reduced Wear and Tear: Efficient motors and durable parts reduce overall wear and tear, resulting in lower long-term expenses.

6. Other Important Factors

Different features may suit specific needs. When choosing an HVAC system, pay attention to:

- Ease of Installation: Systems that are easy to install reduce labor costs and potential issues.

- Safety Standards: Choose systems meeting standard safety regulations, especially for heat handling and electrical components.

- Environmental Impact: Low-emission and energy-efficient models are better for the environment and align with regulatory standards.

| Feature | Recommended Type | Benefits |

|---|---|---|

| Durability | Brushless Motors | Long life, lower maintenance |

| Noise | Quiet Fan Blades | Reduces cabin noise |

| Efficiency | BLDC Motors | Improves energy use and fuel economy |

| EV Compatibility | Compact, lightweight units | Preserves battery life |

Conclusion

The best HVAC system combines durability, low noise, energy efficiency, and EV compatibility. Whether you prioritize cost, durability, or compatibility, consider each factor based on your car’s needs. An efficient, quiet, and durable HVAC system can significantly improve the driving experience, ensuring comfort in every journey.

Automotive HVAC systems are key to a comfortable, safe, and enjoyable ride. They keep us cool in summer and warm in winter. The blower motor plays a major role in distributing this air and making sure it’s just the right temperature.