In the world of automotive, driving a manual-shift car adds an extra layer of connection between the driver and the vehicle, and at the heart of this experience lies a crucial component: the automotive clutch. For those who have maneuvered a stick shift, the clutch is not just another pedal; it’s the third pedal that demands attention and coordination to navigate the gears seamlessly. However, for those accustomed to automatic transmissions, the clutch might be a mysterious entity, often overlooked in its significance. This blog post aims to unravel the mysteries surrounding the clutch, providing comprehensive insights into its functionality and importance.

Understanding the Automotive Clutch Mechanism

In the realm of manual transmission cars, the clutch plays a pivotal role in facilitating gear changes and controlling the engagement between the engine and the wheels. This mechanism is especially crucial for drivers who navigate vehicles with manual transmissions. For those accustomed to automatic transmissions, the clutch might remain a mysterious third pedal. However, its significance becomes apparent when one delves into its underlying function within the internal combustion engine.

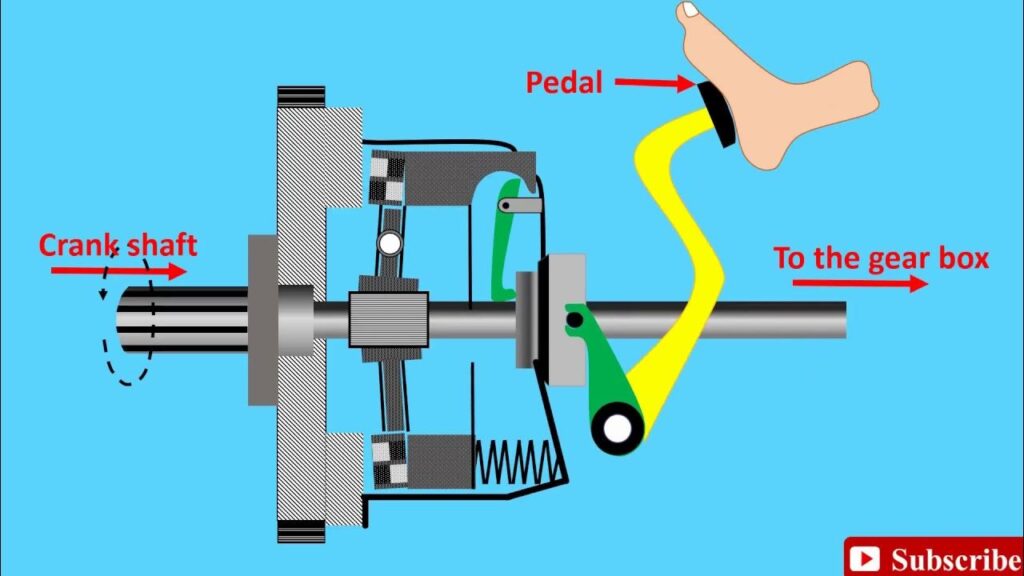

- Function of the Clutch: At its core, the clutch is responsible for both engaging and disengaging the power transmission from the driving shaft to the driven shaft in the engine. This ensures a seamless connection between rotating shafts, a process integral to the functioning of a manual transmission.

- Disengaging the Wheels: Since the engine is in a constant state of motion, the clutch’s primary role is to disengage the wheels, allowing them to come to a halt without shutting down the engine. This decoupling is crucial during gear changes and when the vehicle is stationary, preventing unnecessary wear and tear on engine components.

- Connection of Rotating Shafts: In manual transmissions, the clutch connects rotating shafts originating from the engine to those responsible for turning the wheels. While the engine’s shaft is continually in motion, the clutch ensures that the wheels aren’t consistently spinning, offering control over the transfer of power.

Understanding the clutch mechanism involves recognizing its dynamic involvement in the coordination of these rotating shafts. This synchronization enables the vehicle to smoothly transition between gears, ensuring optimal performance and longevity for both the clutch and the broader transmission system.

Components of a automotive clutch System

The clutch system is a vital component in manual transmission vehicles, ensuring a smooth transition between gears and control over the engine’s power transmission. Let’s delve into the key components that make up this intricate system:

- Clutch Plate:

The clutch plate, also known as a friction disc, is a crucial element of the clutch assembly. Comprising materials like compound organic resin, copper wire, ceramic, or composite paper, the clutch plate serves as a link between the engine and the wheels. When engaged, springs maintain pressure on the clutch plate, enabling the synchronized rotation of the engine and wheel shafts. - Flywheel:

Working in tandem with the clutch plate is the flywheel. This component is connected to the engine and is integral to the disengagement process. The flywheel, being a heavy, rotating disk, assists in maintaining the engine’s momentum during gear changes. When the clutch is engaged, the flywheel ensures a smooth transfer of power between the engine and the wheels. - Springs:

Springs play a pivotal role in the clutch system by exerting pressure on the clutch plate. These springs are responsible for keeping the clutch engaged with the flywheel. The pressure they apply ensures that the clutch plate maintains contact with the flywheel, facilitating the rotation of both components at the same speed. - Release Fork:

To disengage the clutch and interrupt the connection between the engine and the wheels, a release fork comes into play. When the driver depresses the clutch pedal, the release fork applies pressure to the pressure plate, effectively separating it from the clutch plate. This action breaks the connection, allowing the engine to spin independently of the wheels.

Understanding the interplay between these components provides insight into how the clutch system facilitates seamless gear changes in manual transmission vehicles. As drivers engage and disengage the clutch, they control the transfer of power, ensuring a balanced and controlled driving experience. Proper maintenance of these components is crucial for the longevity and optimal performance of the entire clutch system.

Design Variations in Clutches

Understanding the diverse design variations in clutches is crucial for comprehending their applications and functionalities in different vehicles. Here’s a breakdown of the various types:

- Friction Clutches:

- Description: Rely on frictional forces to connect moving members at different speeds.

- Materials: Utilize compound organic resin, copper wire, ceramic, or composite paper for friction.

- Applications: Common in various vehicles, ceramics are often used in racing or heavy-duty situations.

- Multiple Plate Clutches:

- Description: Feature more than one driving member, ideal for high-performance vehicles like Formula 1 and drag racing cars.

- Applications: Widely used in racing scenarios, motorcycles, and diesel engines with mechanical transmissions.

- Cone Clutches:

- Description: Possess a conical shape, allowing for gradual approach or recession, resulting in smoother gear shifting.

- Applications: Found in vehicles where synchronized speeds during gear changes are crucial for performance.

- Centrifugal Clutches:

- Description: Operate based on engine speed, engaging or disengaging the clutch through centrifugal force.

- Applications: Commonly seen in vehicles like mopeds and machinery, where engine speed dictates clutch state.

- Wet versus dry systems:

- Wet Clutches:

- Description: Immersed in a cooling fluid for lubrication, reducing wear and tear.

- Considerations: They tend to be slippery, losing energy, but multiple clutch discs can compensate.

- Applications: Suitable for situations with flow-through cooling methods.

- Dry Clutches:

- Description: Rely on friction for operation and aren’t bathed in liquid.

- Considerations: Lack the slipperiness of wet clutches but may experience more wear.

- Applications: common in various vehicles, offering simplicity and efficiency.

Understanding these design variations allows drivers and mechanics to choose clutches that align with specific vehicle requirements, whether it’s for racing, heavy-duty hauling, or everyday commuting. Each type has its advantages and disadvantages, making it essential to select the right clutch system based on the intended use and performance demands.

Common Clutch Problems

Understanding common clutch problems is essential for vehicle owners to ensure the smooth functioning of their manual transmission systems. Here are some prevalent issues that drivers may encounter:

- Wear:

- Description: Constant friction during normal operation can lead to the wearing out of clutch materials.

- Impact: reduced efficiency and performance as the clutch loses its grip.

- Prevention/Treatment: Regular inspections and avoiding aggressive driving habits can help extend the clutch’s lifespan.

- Broken Cable:

- Description: Tension issues in the clutch cable are responsible for engaging and disengaging the clutch.

- Impact: Inability to shift gears smoothly, resulting in poor vehicle performance.

- Prevention/Treatment: Routine cable checks and replacement as needed to maintain proper tension.

- Leaks:

- Description: Fluid leakage from the clutch cylinders leads to inadequate pressure.

- Impact: impaired clutch functionality; difficulty engaging and disengaging.

- Prevention/Treatment: Regular fluid checks, addressing leaks promptly, and ensuring proper fluid levels.

- Misalignment:

- Description: Incorrect force transmission when pressing the clutch or gas pedal.

- Impact: difficulty in shifting gears; potential damage to other transmission components.

- Prevention/Treatment: Professional alignment checks are performed during routine maintenance to ensure proper force transmission.

- Air in the line:

- Description: The presence of air in the clutch fluid line reduces pressure.

- Impact: inefficient clutch operation, leading to difficulty in gear changes.

- Prevention/Treatment: Bleeding the clutch system to remove air and maintaining proper fluid levels.

- Hard Clutch:

- Description: Increased force is required to operate the clutch pedal.

- Impact: driver discomfort, potential strain on the leg, and difficulty in smooth gear changes.

- Prevention/Treatment: Addressing underlying issues such as cable tension, hydraulic system problems, or worn-out components.

Being aware of these common clutch problems empowers vehicle owners to take proactive measures, ensuring the longevity and optimal performance of their manual transmission systems. Regular maintenance and prompt attention to emerging issues play a crucial role in preventing major breakdowns and costly repairs.

Conclusion

Understanding the role of a clutch is paramount for anyone who has ever operated a manual-shift car. The third pedal, often overlooked by those accustomed to automatic transmissions, holds a critical function in the overall mechanics of a vehicle, particularly in facilitating gear changes. As we’ve explored, the clutch serves as the intermediary between the constantly spinning engine and the wheels, allowing for the necessary disengagement to bring the vehicle to a stop without shutting down the entire engine.

Pingback: Automotive Security: The Best Car Anti-Theft Devices in 2024: Ultimate Guide for Vehicle Security - Buying new and used cars online, and read expert Car review